The Microscopic Research Laboratory (P3) deals with the following research work:

- preparation of metallographic samples,

- hardness measurements using the micro-impressions method,

- microscopic observations using light (LM) and scanning electron microscopy (SEM),

- determining the chemical composition in micro-areas (SEM / EDS).

The research work performed in the Metallographic Research Laboratory is carried out as part of scientific research conducted by the employees of the Department of Materials Science and the Research and Development Laboratory for Aerospace Materials and staffs of other organizational units of Rzeszów University of Technology (PhD students, postdocs , staff from other units involved in industrial projects carried out with group of RUT personnel) and commissioned by external clients - universities: Kraków University of Technology; University of Science and Technology in Kraków (AGH); Silesian University of Technology, Warsaw University of Technology, University of Silesia and production plants: WSK "PZL-Rzeszów" S.A .; Instytut Energetyki Ceramics Division "CEREL" - Boguchwała; Metal Works "DEZAMET"; BURY Technologies; HISPANO-SUIZA - Sędziszów Małopolski, PPHU MLECZMASZ Sp. z o.o., Borg Warner Turbo Systems Poland Sp z o.o. - Jasionka, Factory of Paints and Varnishes Śnieżka -Brzezina; Zakłady Metalowe ERKO - Czeluśnica, MTU Aero Engines Polska - Rzeszów; NORBERT Polska Sp. z o.o. - Rzeszów; ZM INVEST S.A. - Ropczyce.

Research for 4 companies (Pratt&Whitney Rzeszow; CEREL and Borg Warner) is carried out under permanent cooperation agreements.

The basic equipment of the metallographic research laboratory includes:

- A set of devices for the preparation of metallographic specimens consisting of:

- Discotom-6 universal cutter

- Accutom-50 automatic precision cutter

- Struers Epovac vacuum mounting devices

- LaboPress-3 automatic hot mounting press

- handheld sander-polisher LaboPol-25

- Tegra Pol-25 automatic grinding and polishing machine

- Stereoscopic microscope with a parallel optical path Nikon SMZ 1000 - equipped with a digital image archiving system and software for controlling the microscope, archiving and analyzing images (Lucia program).

- Nikon EPIPHOT 300 metallographic microscope - magnification 50x to 1000x - for observing the microstructure of metals, metal alloys, ceramics and composites. An automatic table, Nikon DS-5 digital camera and software, which works with the microscope, enable measurement, analysis of the stereological parameters of the microstructure and their archiving (Lucia program).

- Scanning electron microscope (SEM) HITACHI S-3400N - magnification 5x to 100,000x - for observing the surface of metallic materials, with the possibility of observing non-conductive materials (low vacuum) with EDS and WDS systems for chemical composition analysis and EBSD for determining the texture of materials, directions crystallographic single crystals, preparation of crystal orientation maps, phase identification and determination of phase morphology - components of the microstructure.

- Automatic micro-coating machine Cressington 108auto for conductive coating of SEM/EDX microscopic samples, equipped with a magnetron ensuring high efficiency and low heating of the samples.

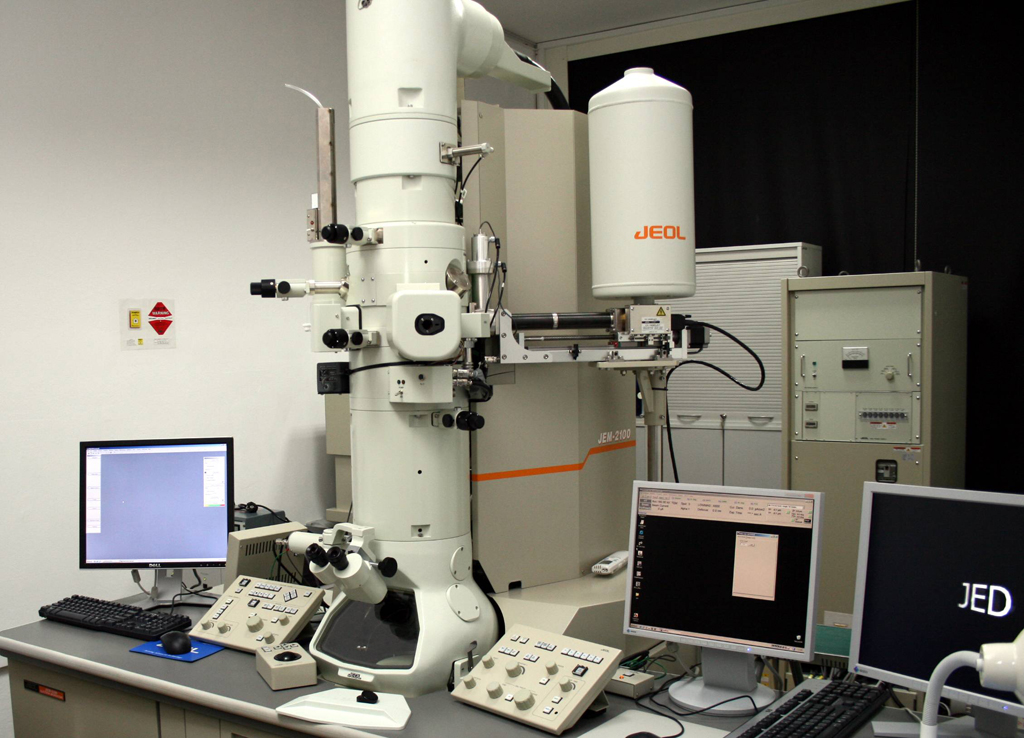

- Transmission electron microscope (TEM) JEOL JEM – 2100 - high resolution, voltage 200kV, with EDS system and digital image recording system.

- Precision Ion Polishing System GATAN Model 691 - for the preparation of thin films - preparations for observation using a transmission electron microscope from semiconductors, ceramics, metals and their alloys, composites, superconductors, heat-sensitive materials.