The Laboratory of Mechanical Properties Testing (P1) conducts research on the mechanical properties of structural materials, mainly metal alloys, as well as ceramic and composite materials, with particular emphasis on materials used in the aviation industry.

The following types of tests are performed:

- static tensile, compression and bending test at room temperature;

- static tensile test at elevated temperature (Tmax = 1100°C);

- creep test (Tmax = 1100°C);

- fatigue test in the range of a small number of cycles (tension-compression) at constant stress or constant strain;

- fatigue test in the range of a large number of cycles (tension-compression, torsion, double-sided bending) at constant stress;

- room temperature impact test (Charpy method);

- Brinell, Vickers and Rockwell hardness measurements;

The lab is equipped with:

- electromechanical testing machine Galdabini Quasar 600 (maximum load Fmax = 600 kN)

- four universal electromechanical testing machines (Instron, UTS-Zwick; Fmax = 100 kN),

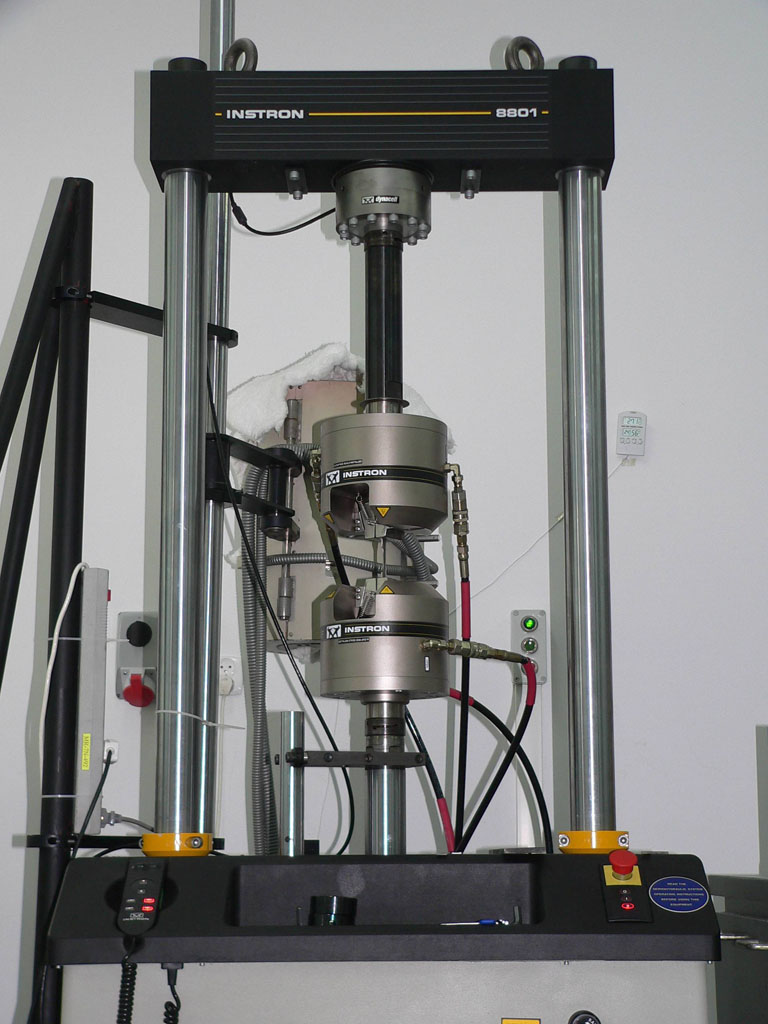

- hydraulic testing machine Instron 8801 (Fmax = 100 kN),

- electromechanical creep machine Zwick Kappa 50 DS (Fmax = 50kN),

- dead weight creep machine Zwick Kappa 50 LA (Fmax = 50kN),

- two-station electromechanical creep machine Walter + Bai AG LFMZ-30kN (Fmax = 30kN)

- RUMUL Cracktronic resonance fatigue machine

- Charpy impact testing machine ZWICK BRA342038205 (E = 300J)

- universal hardness testers Zwick ZHU 250 and Wolpert Instron

- pulsator LDS V830-185 600 COMBO with CH1200C climatic chamber Angelantoni Industrie Sp.A. (operating temperature range from -70 to + 180°C)

The available equipment for testing machines enables tensile tests to be carried out at room temperature on flat (using wedge grips) or cylindrical specimens (both threaded-end and shouldered-end). The measurement of deformation during the test is carried out using mechanical extensometers, both static and dynamic.