The Laboratory of Thermal Analysis (P7) is equipped with:

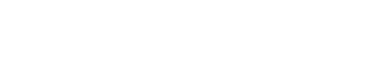

- The STA 449 F1 Jupiter NETZSCH is a measuring unit that enables a wide range of thermal analysis from minerals, inorganic substances, metals and alloys, ceramics, polymers, to pharmaceuticals, food and biological materials. The STA 449 F1 Jupiter enables the comprehensive study of thermal stability, material composition, phase changes and material decomposition processes. The methods used in STA measurements include: thermogravimetric analysis (TGA), differential thermal analysis (DTA), differential scanning calorimetry (DSC). However, when using the comparative method of the DSC curves of sapphire and the tested sample, the specific heat of the tested material can be additionally determined based on the ASTM E 1269 and DIN 51 007 standards. determination of thermal properties of organic substances, inorganic liquids and solids. This technique allows, among others on the detailed characteristics of the mechanisms of chemical processes taking place in the tested sample during its heating.

Technical data:

- Temperature range 25 ÷ 1650 ° C

- Weighing range: 0 ÷ 35 g

- Resolution: 1μg (full range)

- Calorimetric accuracy ± 3%

- RMS noise floor for DSC mode not more than 10μW

- Calorimetric sensitivity in DSC mode at least 1μW

- Baseline repeatability for DSC mode no worse than ± 1mW

- Baseline linearity for DSC mode not worse than ± 2.5mW

- The system is equipped with an automated vacuum system

- The user can quickly replace the sample carriers (TG-DTA, TG, TG-DSC) depending on the measuring task

- Heating rate in the range from 0.01 to 50 K / min

- The analyzer is equipped with a specific heat measurement kit (cp calibration standards, software).

- EGA analyzer - heated gas chamber: max 200 ° C,

- Detector: DLaTGS, FT-IR spectrum range: 6000 cm-1 to 500 cm-1, Gas cell windows made of ZnSe

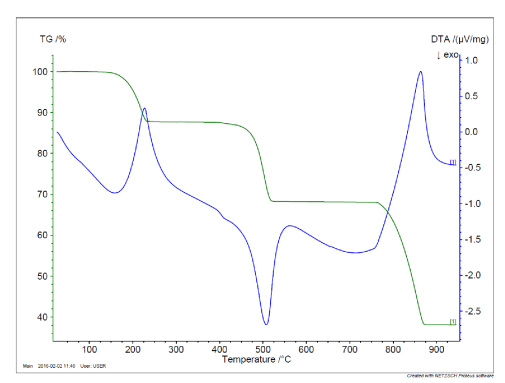

- The Dil 402C dilatometer NETZSCH is a device on which tests can be performed, the purpose of which is to determine in the tested metal or its alloy, as well as in ceramic and polymer material, based on the recorded changes in the length of the sample subjected to the assumed thermal treatments, the beginning and end of phase changes, determination thermal linear expansion coefficients or determining the processes taking place during various thermal treatments by imitating these treatments in the DIL 402C dilatometer, both in any static and dynamic atmospheres and vacuums.

Technical data:

- measuring range of the dilatometer: ± 500/5000 μm,

- Δl resolution: 0.125 nm / 1.25 nm,

- range of pressure of the pusher on the sample from 15 to 45 cN,

- sample holder and special sample holders made of Al2O3,

- maximum dimensions of test samples: Ø 12 mm, length up to 25 mm,

- the possibility of making measurements in a static or dynamic atmosphere or in a vacuum,

- the possibility of taking measurements in the temperature range from 20 to 1600 ° C,

- dilatometer with a horizontally working pusher,

- programming of measuring cycles (up to 245 stages).

- the dilatometer is equipped with special crucibles for measuring pastes or powders.

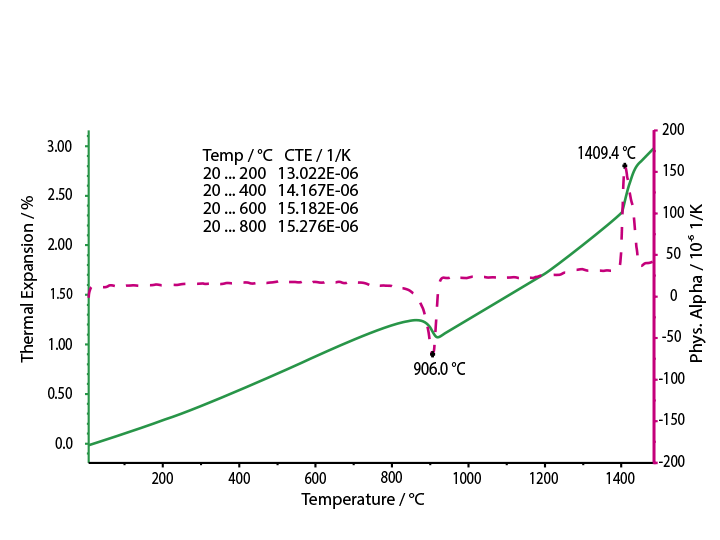

- LFA 427 NETZSCH is one of the most precise and versatile instruments used in the Laser Pulse Method. This device allows the study of important thermophysical parameters of materials, i.e. thermal conductivity and thermal diffusivity, which are necessary in the description of heat transport phenomena of the analyzed materials. LFA 427 for the determination of thermal conductivity uses a method involving the measurement of thermal diffusivity, specific heat and density as a function of temperature, and then the determination of thermal conductivity from these data. The laser pulse method provides non-contact measurement of thermal diffusivity through an IR detector, thermal diffusivity measurements in the range: 0.01 - 1000 mm2/s, thermal conductivity measurements 0.1 - 2000 W/mK, temperature range: 20 - 2000°C, argon atmosphere. Dimensions of samples: cylindrical: diameter 12.6 mm, height from 0.1 to 6 mm, rectangular: cross-section 10 x 10 mm, height 0.1 to 6 mm. The device enables the measurement of specific heat.

Technical data:

- Temperature range of measurement: 18°C - 2000°C

- Heating/cooling rate: 0.01 K/min - 50K/min

- Laser power: 20J/pulse (adjustable power and pulse length)

- Non-contact measurement of temperature rise by IR detector

- Thermal diffusivity measuring range: 0.01 mm2/s - 1000 mm2/s

- Thermal conductivity measuring range: 0.1 W/mK - 2000 W/mK

- Sample carrier: Al2O3, graphite

- Atmosphere: Argon

- round samples: diameter: 12.5 mm, thickness: 0.1 mm - 6 mm

- The Micromeritics AccuPyc 1330 gas pycnometer allows to measure the specific (true) density of solids. Measurements are performed in a helium atmosphere. The use of helium enables the analysis of porous bodies and bodies with a highly developed surface. The AccuPyc 1330 gas pycnometer can analyze solids, porous solids and powders. It is a non-destructive test.

Technical data:

- filling pressure of helium chamber: 19.5 psig

- measurement accuracy: 0.03%

- measurement repeatability: ± 0.01%

- The Micromeritics quasi-liquid pycnometer GeoPyc 1360 allows to measure the bulk density (apparent) density of solids. The apparatus carries out precise measurement of the sample volume. This measurement takes place in an environment of the quasi-liquid DryFlo ™ substance. In the GeoPyc 1360 quasi-liquid pycnometer, you can analyze solids of various shapes and sizes, including samples consisting of several parts (with dimensions from 2 mm). It is a non-destructive test. Tests in a quasi-liquid pycnometer provide sample parameters such as:

- bulk density (apparent),

- volume,

- porosity (after entering the value of specific - real density),

- the bulk density of the powders.

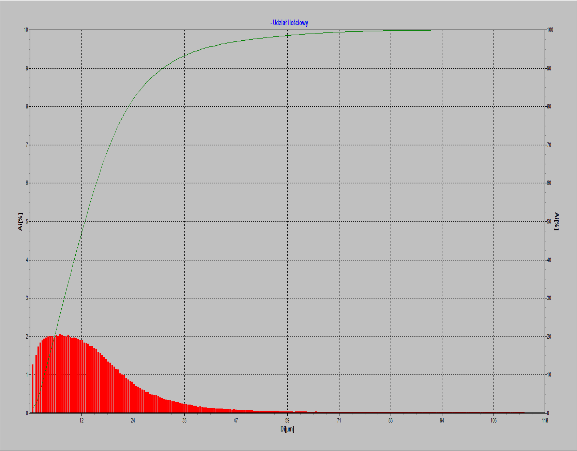

- The KAMIKA IPS U is a device for measuring the size distribution of solid particles in the air in laboratory conditions, regardless of their physical and chemical properties. It is used for measuring the size of wet and sticking particles from 0.5μm to 600μm, reading the second average particle size and determining the shape factor, determining the specific surface area of the tested substances.

Technical data:

- measuring range: 0.5 - 1000 µm

- number of measurement classes: 256

- light source: Infrared diode

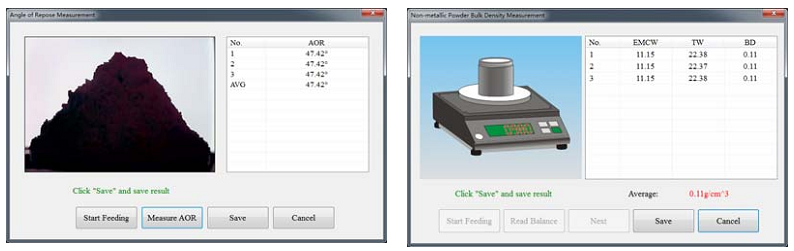

- BT-1001 intelligent powder material property tester - The physical properties of the powder substance are its basic feature. Testing the physical properties of powders is of practical importance in the production, processing, packaging, transport, storage, application, etc. Although the physical properties of powdered substances are of such great practical importance, testing them is an arduous and lengthy process. Due to the low accuracy of the measurements and the instability of the results, they cannot be a decisive factor in the design work in powder engineering. In order to achieve scientific, simple, fast and accurate powder testing results, Bettersize Instruments Ltd. has developed a physical properties tester for powder substances called BT-1001. This new type of physical test instrument integrates many modern measurement techniques that make measurements of physical properties scientific, intelligent and accurate. Measurements made by the intelligent BT-1001 tester include the following powder properties: angle of refraction, angle of internal friction (chute), flowability and fluidity coefficient, etc. The instrument is characterized by high intelligence, multi-functionality, simple operation, good repeatability of results, flexible measurement conditions and compatibility with a number of standards. Due to its successful development, the instrument provides precise scientific tools for measuring the physical properties of powder substances.

- Main features of the BT-1001 tester:

|

No. |

Property measured |

Specification |

|

1 |

Repose angle |

0 - 90º, imaging testing |

|

2 |

Collapse angle |

0 - 90º, imaging testing |

|

3 |

Difference angle |

0 - 90º, automatic calculations |

|

8 |

Bulk density |

Constant volume or constant weight method |

-

Good repeatability: (1) Reasons for good repeatability: a) Imaging for internal friction angle and plane angle measurements using CCD dies and precise software calculations; b) the screen vibration frequency is continuously adjustable, which allows for even dosing of the sample; c) all testing processes are performed automatically, eliminating the possibility of operator error.

-

Example of repeatability verification: repeatability of a repeat test of the same sample:

Tested quantities and coefficients measured by the BT-1001 tester:

- Repose angle: in a state of static equilibrium, the acute angle between the natural slope of the slope and the lower horizontal plane of the powder substance is called the internal friction (embankment) angle. With the use of electromagnetic vibrations, it is formed by powder substances that freely fall onto a stationary platform. The angle of internal friction directly reflects the flow properties of the powder. If the angle of repose is smaller, the flowability is greater. If the angle of repose is greater, the flowability is less. The angle of internal friction is also called the angle of rest or the natural angle of inclination.

- Collapse angle: after measuring the angle of internal friction, the impact on the sprinkled powder with external forces will cause its surface to collapse. The acute angle between the powder slope and the lower horizontal plane is called the angle of refraction. If the angle of refraction is smaller, the flowability of the powder is better.

- Difference angle: The difference between the internal friction angle and the refraction angle is called the differential angle. The greater the difference, the greater the splash property coefficient of the powder substance.

- Bulk density: defines the density of the powder in a specific container in its natural state.